Customize to suit your expectations

For reagent companies in order to remain competitive and maximize growth, the need of an automated solutions suited for their products becomes a critical driver for next level expansion. However, facing with the high cost of design, quality production capabilities, lack of expertise, and production costs, these factors all barriers for companies to enter the automated instrument space.

NAYO’s innovative FAN platform, through its unique modular design, an established rapid delivery capability, and its ability to address different needs provides a strong automated solution to any of our partner’s products. The FAN platform significantly reduces time from design to product, while cutting delivery cycles from several months to just weeks—with lead times as short as 15 days.

At NAYO, we have a new state of the art factory, along with a strong vertical production chain to process from raw materials all the way to the final parts/modules. Thus, ensuring a reliable quality and stability of all the units and parts produced. The FAN process also provides for easy upgrade/updates to newer technologies as we aim to keep up with innovations improvements of our customers with comparable automated equipment to ensure we stay ahead of the competition. We have enabled global enterprises to efficiently address their liquid handling automation challenges.

NAYO’s innovative FAN platform, through its unique modular design, an established rapid delivery capability, and its ability to address different needs provides a strong automated solution to any of our partner’s products. The FAN platform significantly reduces time from design to product, while cutting delivery cycles from several months to just weeks—with lead times as short as 15 days.

At NAYO, we have a new state of the art factory, along with a strong vertical production chain to process from raw materials all the way to the final parts/modules. Thus, ensuring a reliable quality and stability of all the units and parts produced. The FAN process also provides for easy upgrade/updates to newer technologies as we aim to keep up with innovations improvements of our customers with comparable automated equipment to ensure we stay ahead of the competition. We have enabled global enterprises to efficiently address their liquid handling automation challenges.

FAN Standard Configurator: Your First Steps to Automation.

On the FAN platform, you can configure your desired automated liquid handling workstation in just 4 steps by

selecting the base unit, the multi-function arm (MFA), the bench layout, and accessory.

selecting the base unit, the multi-function arm (MFA), the bench layout, and accessory.

STEP 1

Base Unit

A8 mini

Benchtop Automated Liquid Handling Workstation

The A8 mini is a compact, benchtop liquid handling workstation designed for labs with limited bench space. Based on one single arm, it offers over 10 configurations for unparalleled flexibility:

• Pipetting Modules: single-channel, dual-channel, flexible 4-channel, and fixed 8-channel

• Extended Module: Configurable with adaptive force gripper module

• Multi-Function Arm (MFA): Support the combined use of a fixed 8-channel pipetting module, flexible-channel pipetting modules, and extended modules

The workstation features 12 standard SBS-compatible deck slots and can integrate up to three functional modules simultaneously—such as temperature control modules (TCM), automated shaker modules (ASM), fluorescence readers, or other third-party devices. All multi-function arms and on-deck modules support tool-free quick swapping capability within 3 minutes.

Beyond high-precision pipetting, the A8 mini streamlines complex workflows including concentration normalization, clone picking, sample pooling, and various purification assays. Its modularity enables multi-application utility in one single workstation, making it an ideal choice for short workflows automation that demands flexibility, efficiency and a high return on investment.

Benchtop Automated Liquid Handling Workstation

The A8 mini is a compact, benchtop liquid handling workstation designed for labs with limited bench space. Based on one single arm, it offers over 10 configurations for unparalleled flexibility:

• Pipetting Modules: single-channel, dual-channel, flexible 4-channel, and fixed 8-channel

• Extended Module: Configurable with adaptive force gripper module

• Multi-Function Arm (MFA): Support the combined use of a fixed 8-channel pipetting module, flexible-channel pipetting modules, and extended modules

The workstation features 12 standard SBS-compatible deck slots and can integrate up to three functional modules simultaneously—such as temperature control modules (TCM), automated shaker modules (ASM), fluorescence readers, or other third-party devices. All multi-function arms and on-deck modules support tool-free quick swapping capability within 3 minutes.

Beyond high-precision pipetting, the A8 mini streamlines complex workflows including concentration normalization, clone picking, sample pooling, and various purification assays. Its modularity enables multi-application utility in one single workstation, making it an ideal choice for short workflows automation that demands flexibility, efficiency and a high return on investment.

A8 pro

Automated Liquid Handing Workstation

The A8 pro is a flexibly scalable, professional-grade liquid handling platform. It supports configurations with either a single arm or dual arms, offering over 24 optional combination setups:

• Pipetting Modules: single-channel, dual-channel, flexible 4-channel, flexible 8-channel, flexible 12-channel, fixed 8-channel, and fixed 24-channel

• Extended Modules: Configurable with adaptive force gripper module and tube rotation and gripper module

• Multi-Function Arm (MFA): Support the combined use of one fixed 8-channel / fixed 24-channel pipetting module, flexible-channel pipetting modules, and extended modules

With a deck capacity of up to 60 SBS-compatible slots, it can integrate multiple functional modules simultaneously to meet the demands of long and complex experimental workflows.

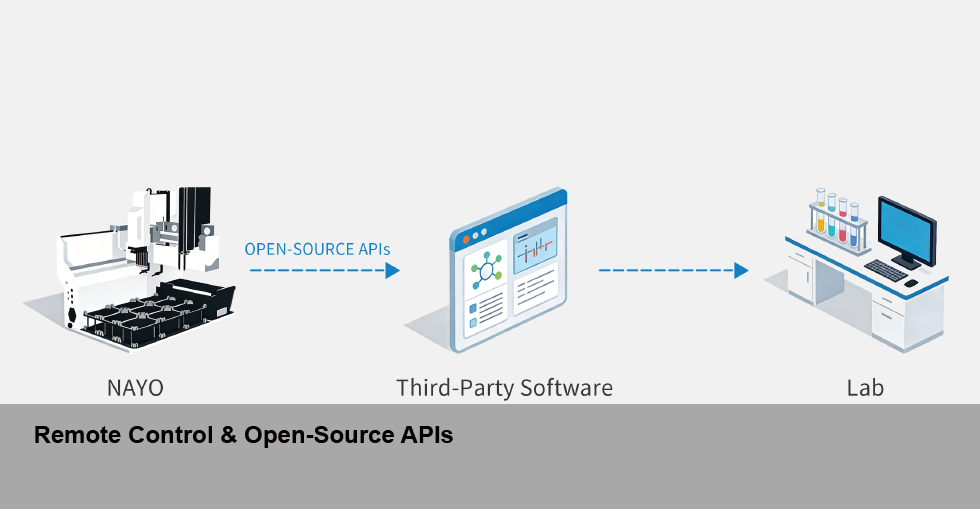

By integrating third-party device, the A8 pro enables complete end-to-end automation from sample preparation to result analysis, delivering a highly reliable and scalable automation solution for R&D and testing laboratories.

Automated Liquid Handing Workstation

The A8 pro is a flexibly scalable, professional-grade liquid handling platform. It supports configurations with either a single arm or dual arms, offering over 24 optional combination setups:

• Pipetting Modules: single-channel, dual-channel, flexible 4-channel, flexible 8-channel, flexible 12-channel, fixed 8-channel, and fixed 24-channel

• Extended Modules: Configurable with adaptive force gripper module and tube rotation and gripper module

• Multi-Function Arm (MFA): Support the combined use of one fixed 8-channel / fixed 24-channel pipetting module, flexible-channel pipetting modules, and extended modules

With a deck capacity of up to 60 SBS-compatible slots, it can integrate multiple functional modules simultaneously to meet the demands of long and complex experimental workflows.

By integrating third-party device, the A8 pro enables complete end-to-end automation from sample preparation to result analysis, delivering a highly reliable and scalable automation solution for R&D and testing laboratories.

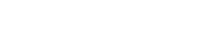

A96

Automated Liquid Handling Workstation

The A96 is an automated liquid handling platform designed for high-throughput applications. It features a high-precision 96-channel pipetting module and supports configurations with either a single arm or dual arms.

In a dual-arm setup, one arm is dedicated to the fixed 96-channel pipetting module, while the other can be equipped with an optional flexible 4-channel or 8-channel pipetting module. This enables collaborative workflows for efficient bulk dispensing and precise reagent addition.

• Pipetting Modules: single-channel, dual-channel, flexible 4-channel, flexible 8-channel, and fixed 96-channel

• Extended Modules: Configurable with adaptive force gripper module and tube rotation and gripper module

• Multi-Function Arm (MFA): Support the combined use of one fixed 96-channel pipetting module, flexible-channel pipetting modules, and extended modules

With a deck capacity of up to 60 SBS-compatible slots, it can integrate various functional modules including temperature control, shaking, detection units, and more, to meet the requirements of larger-scale and longer experimental workflows.

By integrating third-party device, the A96 enables a high-throughput, end-to-end automated solution—from sample to result.

Automated Liquid Handling Workstation

The A96 is an automated liquid handling platform designed for high-throughput applications. It features a high-precision 96-channel pipetting module and supports configurations with either a single arm or dual arms.

In a dual-arm setup, one arm is dedicated to the fixed 96-channel pipetting module, while the other can be equipped with an optional flexible 4-channel or 8-channel pipetting module. This enables collaborative workflows for efficient bulk dispensing and precise reagent addition.

• Pipetting Modules: single-channel, dual-channel, flexible 4-channel, flexible 8-channel, and fixed 96-channel

• Extended Modules: Configurable with adaptive force gripper module and tube rotation and gripper module

• Multi-Function Arm (MFA): Support the combined use of one fixed 96-channel pipetting module, flexible-channel pipetting modules, and extended modules

With a deck capacity of up to 60 SBS-compatible slots, it can integrate various functional modules including temperature control, shaking, detection units, and more, to meet the requirements of larger-scale and longer experimental workflows.

By integrating third-party device, the A96 enables a high-throughput, end-to-end automated solution—from sample to result.

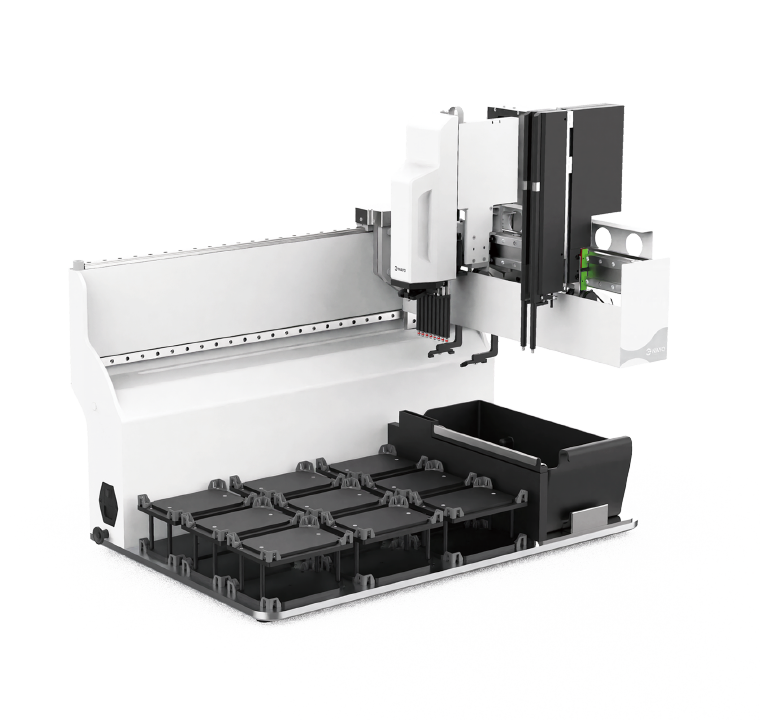

N96 S

Benchtop Automated Liquid Handling Workstation

The N96 S is a benchtop liquid handling platform designed for high-throughput applications. Equipped with a high-precision fixed 96-channel pipetting module and an optional adaptive force gripper module, it perfectly balances operational efficiency with procedural flexibility.

• Standard Configuration: Support a fixed 96-channel pipetting module

• Extended Capability: Support seamless synergy between the fixed 96-channel pipetting module and an integrated adaptive force gripper module

The platform supports 4 or 6 SBS-compatible deck slots and can be integrated with various functional modules such as temperature control, shaking, detection, and more.

By connecting with third-party device, the N96 S provides a compact automation solution for medium- to small-scale high-throughput experiments, from sample preparation to result output.

Benchtop Automated Liquid Handling Workstation

The N96 S is a benchtop liquid handling platform designed for high-throughput applications. Equipped with a high-precision fixed 96-channel pipetting module and an optional adaptive force gripper module, it perfectly balances operational efficiency with procedural flexibility.

• Standard Configuration: Support a fixed 96-channel pipetting module

• Extended Capability: Support seamless synergy between the fixed 96-channel pipetting module and an integrated adaptive force gripper module

The platform supports 4 or 6 SBS-compatible deck slots and can be integrated with various functional modules such as temperature control, shaking, detection, and more.

By connecting with third-party device, the N96 S provides a compact automation solution for medium- to small-scale high-throughput experiments, from sample preparation to result output.

| ||

| Base Unit | Dimensions (L*W*H) | No. of Deck Slots |

| A8 mini | 665 mm x 525 mm x 610 mm | 12 |

| A8 pro | 790 mm x 740 mm x 980 mm | 20 |

| A8 pro | 1240 mm x 740 mm x 980 mm | 35 |

| A96 | 790 mm x 740 mm x 1168 mm | 20 |

| A96 | 1240 mm x 740 mm x 1168 mm | 35 |

| N96 S | 711 mm x 392 mm x 582 mm | 4 |

| N96 S | 998 mm x 392 mm x 582 mm | 6 |

❈ A8 pro & A96 can be customized deck capacity up to 60 deck slots.

STEP 2

Pipetting Head and Multi-Function Arm (MFA)

❈ Additional non-standard set up can be customized to your needs.

STEP 3

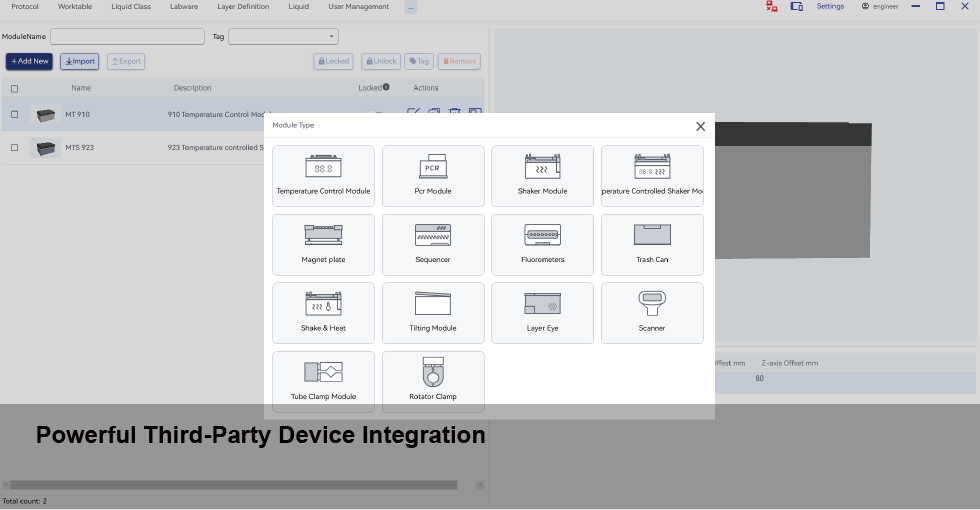

On-Deck Modules

Designed for Integration, Easy Use and Precision.

• Stable and Wide Speed Range: Covering from 0 to 5000 rpm, it effortlessly handles diverse workflows, from gentle homogenization to vigorous shaking, suitable for a wide variety of liquids.

• Accurate Temperature Control: The innovative temperature control system enables precise heating and cooling, which is crucial for temperature-sensitive experimental steps.

• Low-Profile Modular Design: It features a small footprint and a compact form factor, effectively saving valuable laboratory bench space.

• Easy to Use and Install: With quick plug-and-play operation, it offers the flexibility to switch rapidly between different workflows, significantly improving experimental efficiency and reliability.

• Stable and Wide Speed Range: Covering from 0 to 5000 rpm, it effortlessly handles diverse workflows, from gentle homogenization to vigorous shaking, suitable for a wide variety of liquids.

• Accurate Temperature Control: The innovative temperature control system enables precise heating and cooling, which is crucial for temperature-sensitive experimental steps.

• Low-Profile Modular Design: It features a small footprint and a compact form factor, effectively saving valuable laboratory bench space.

• Easy to Use and Install: With quick plug-and-play operation, it offers the flexibility to switch rapidly between different workflows, significantly improving experimental efficiency and reliability.

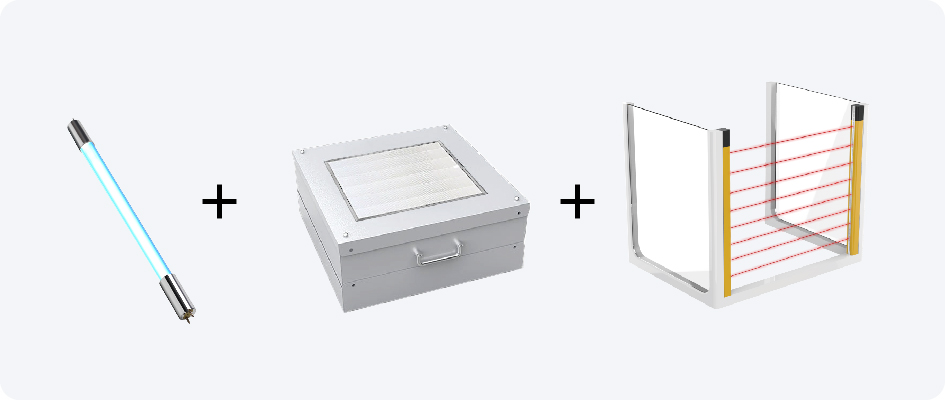

STEP 4

Additional Accessories

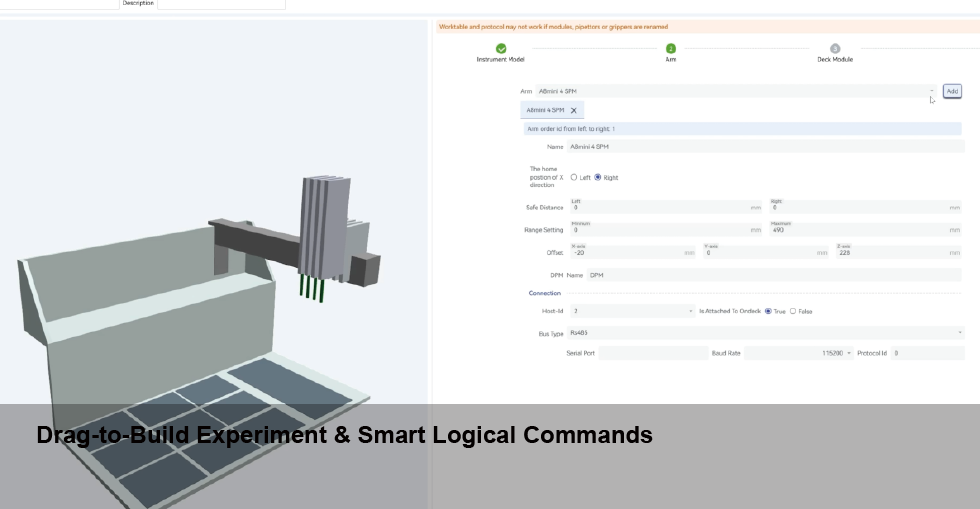

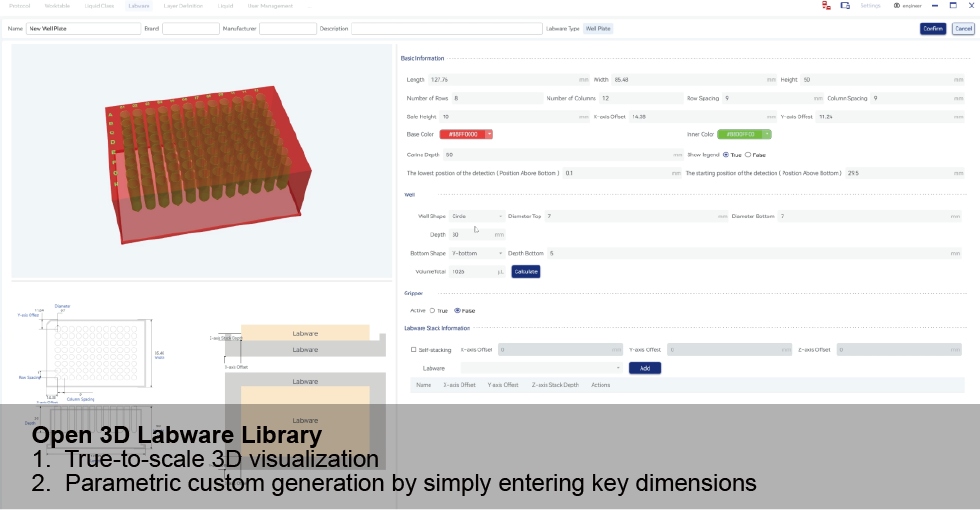

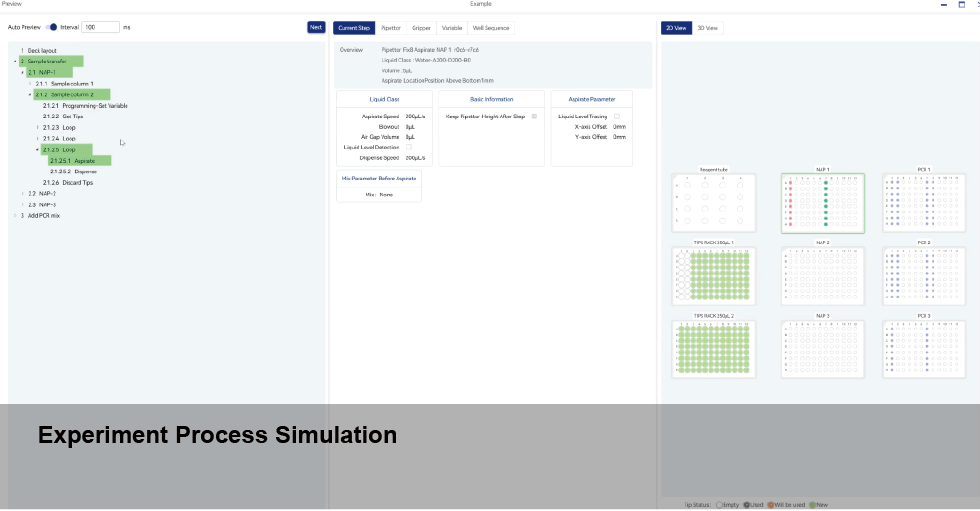

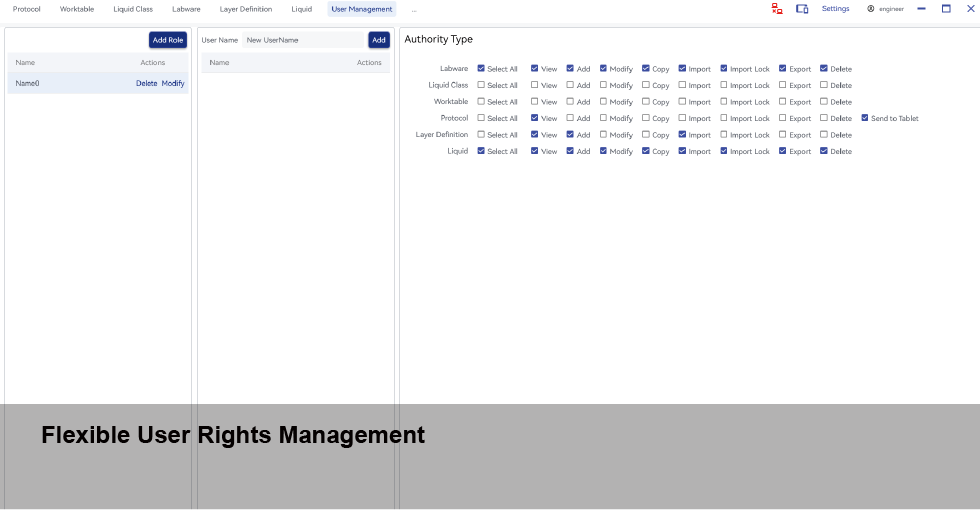

Intuitive Software: Low-Barrier Interface

with No Special Training Needed.

with No Special Training Needed.

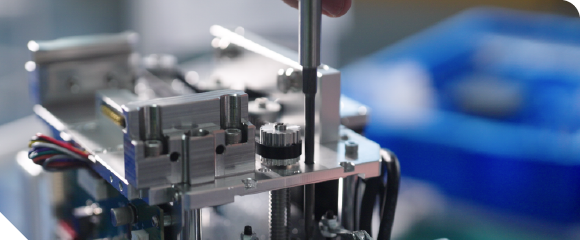

Quick Installation and Self-Service Maintenance

POGO PIN technology enables modular assembly and disassembly of products, facilitating precise fault localization and rapid repair of individual components.

This eliminates the need for on-site technician maintenance, thereby reducing POGO wait times.

This eliminates the need for on-site technician maintenance, thereby reducing POGO wait times.

Pressure Liquid Level Detection

Pipette Specifications

Range 1~1000μL

| Tip Capacity | Tested Volume | Accuracy %D | Precision %CV |

| 50 μL | 1 μL | 10 | 8 |

| 50 μL | 2 μL | 8 | 4 |

| 50 μL | 5 μL | 4 | 4 |

| 50 μL | 50 μL | 1 | 1 |

| 250 μL | 50 μL | 1 | 1 |

| 250 μL | 250 μL | 1 | 1 |

| 1000 μL | 100 μL | 1 | 1 |

| 1000 μL | 500 μL | 0.5 | 0.5 |

| 1000 μL | 1000 μL | 0.5 | 0.5 |

Range 0.7~300μL

| Tip Capacity | Tested Volume | Accuracy %D | Precision %CV |

| 50 μL | 0.7 μL | 12 | 10 |

| 50 μL | 1 μL | 8 | 8 |

| 50 μL | 10 μL | 3 | 3 |

| 50 μL | 50 μL | 1 | 1 |

| 250 μL | 50 μL | 1 | 1 |

| 250 μL | 100 μL | 0.5 | 0.5 |

| 250 μL | 250 μL | 0.5 | 0.5 |

| 1000 μL | 100 μL | 1 | 1 |

| 1000 μL | 300 μL | 1 | 1 |

Modern factories with large-scale production

from raw materials to finished goods along with a full-process

quality control system throughout the entire process.

from raw materials to finished goods along with a full-process

quality control system throughout the entire process.

Success Story