Product

Standardize Your Short Workflows

• Compact Design: The A8 mini (L 665 mm x W 525 mm x H 610 mm) fits easily inside a biological safety cabinet, freeing up bench space while providing dual protection for both the operator and samples.

• Ultimate Flexibility: Supports tool-free, quick-swap of various pipetting and on-deck modules, enabling rapid adaptation to diverse experimental workflows.

• Easy Self-Installation: Users can complete setup and basic calibration independently, significantly reducing the lead time from delivery to operation.

• Ultimate Flexibility: Supports tool-free, quick-swap of various pipetting and on-deck modules, enabling rapid adaptation to diverse experimental workflows.

• Easy Self-Installation: Users can complete setup and basic calibration independently, significantly reducing the lead time from delivery to operation.

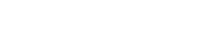

A8 mini

Benchtop Automated Liquid Handling Workstation

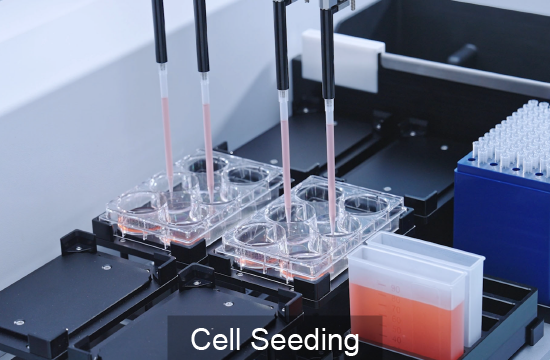

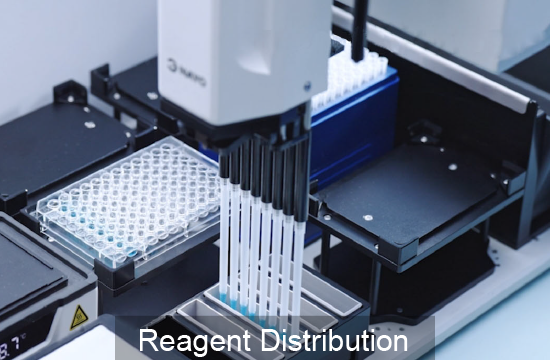

The A8 mini is a compact, benchtop liquid handling workstation designed for labs with limited bench space. Based on one single arm, it offers over 10 configurations for unparalleled flexibility:

• Pipetting Modules: single-channel, dual-channel, flexible 4-channel, and fixed 8-channel

• Extended Module: Configurable with adaptive force gripper module

• Multi-Function Arm (MFA): Support the combined use of a fixed 8-channel pipetting module, flexible-channel pipetting modules, and extended modules

The workstation features 12 standard SBS-compatible deck slots and can integrate up to three functional modules simultaneously—such as temperature control modules (TCM), automated shaker modules (ASM), fluorescence readers, or other third-party devices. All multi-function arms and on-deck modules support tool-free quick swapping capability within 3 minutes.

Beyond high-precision pipetting, the A8 mini streamlines complex workflows including concentration normalization, clone picking, sample pooling, and various purification assays. Its modularity enables multi-application utility in one single workstation, making it an ideal choice for short workflows automation that demands flexibility, efficiency and a high return on investment.

Benchtop Automated Liquid Handling Workstation

The A8 mini is a compact, benchtop liquid handling workstation designed for labs with limited bench space. Based on one single arm, it offers over 10 configurations for unparalleled flexibility:

• Pipetting Modules: single-channel, dual-channel, flexible 4-channel, and fixed 8-channel

• Extended Module: Configurable with adaptive force gripper module

• Multi-Function Arm (MFA): Support the combined use of a fixed 8-channel pipetting module, flexible-channel pipetting modules, and extended modules

The workstation features 12 standard SBS-compatible deck slots and can integrate up to three functional modules simultaneously—such as temperature control modules (TCM), automated shaker modules (ASM), fluorescence readers, or other third-party devices. All multi-function arms and on-deck modules support tool-free quick swapping capability within 3 minutes.

Beyond high-precision pipetting, the A8 mini streamlines complex workflows including concentration normalization, clone picking, sample pooling, and various purification assays. Its modularity enables multi-application utility in one single workstation, making it an ideal choice for short workflows automation that demands flexibility, efficiency and a high return on investment.

Simple, Compact, Ready out of the Box

Pogo Pin Design

25 mins from unboxing to device activation.

Pipetting Head

• Pipetting Head features a unique modular deign along with pLLD and DPC functions providing a wide range of coverage form 1-1000 µL.

• Unique sealing design help extend head life time and reliability up to 300,000 times before needing replacements.

• Unique sealing design help extend head life time and reliability up to 300,000 times before needing replacements.

Pipetting Technology

|

|

|

|

Adaptive Force Gripper

Precise force-controlled gripper

• Accurate gripper with precise force control ranging 1-16N providing seamless transfer of various consumables.

• The finger direction can be configured forward/backward according to requirements.

• Accurate gripper with precise force control ranging 1-16N providing seamless transfer of various consumables.

• The finger direction can be configured forward/backward according to requirements.

Integration Functional Modules

We differentiate ourselves by delivering seamless integration interfaces to meet your customization requirements.

- Automated Shaker Module (ASM)

- High shaker stability and safety

- Automatic in-situ position and clamping

- Heater Shaker Module (HSM)

- Built-in heating unit ensures rapid temperature rise

- Automatic in-situ position and clamping

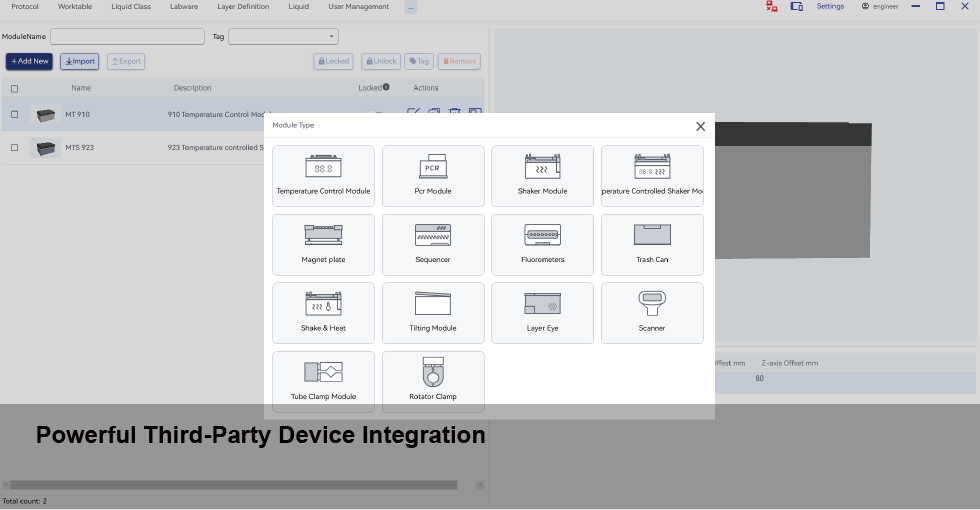

- The Third-Party Device Integration

- Including Fluorescence Quantitative, and more

- Temperature-controlled Shaker Module (TCS)

- Precise temperature control

- Rapid response to temperature changes

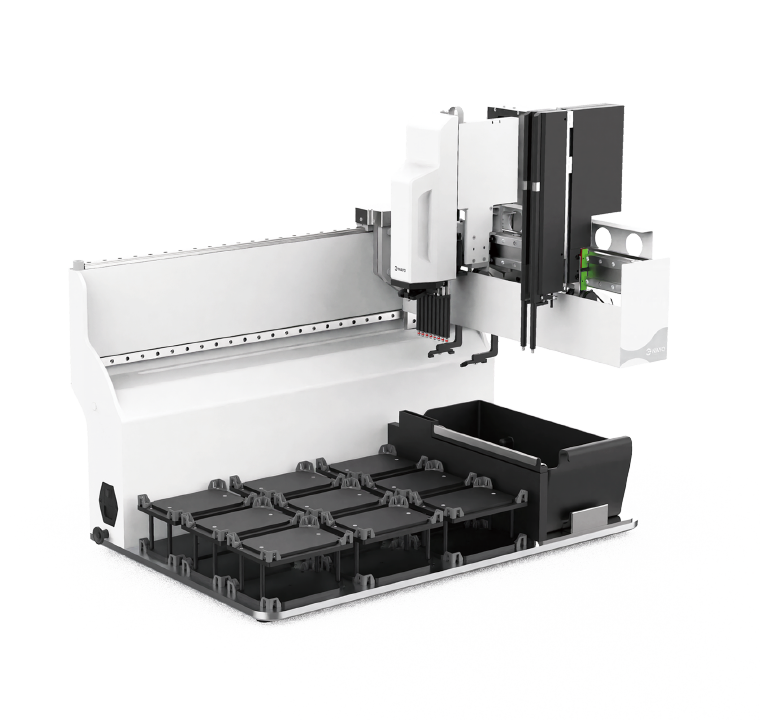

- Temperature Control Module (TCM)

- Wide range of temperature control

- Rapid response to temperature changes

- Layer Eye

- A unified 3-in-1 solution integrating high-speed barcode identification, vision-based interface detection, and automated capping/decapping

On-Deck Modules with High Integration and Compatibility

- Adapt to diverse experimental scenarios flexibly with

- Stable and Wide Speed Range: Covering from 0 to 5000 rpm, it effortlessly handles diverse workflows, from gentle homogenization to vigorous shaking, suitable for a wide variety of liquids.

- Accurate Temperature Control: The innovative temperature control system enables precise heating and cooling, which is crucial for temperature-sensitive experimental steps.

- Low-Profile Modular Design: It features a small footprint and a compact form factor, effectively saving valuable laboratory bench space.

- Easy to Use and Install: With quick plug-and-play operation, it offers the flexibility to switch rapidly between different workflows, significantly improving experimental efficiency and reliability.

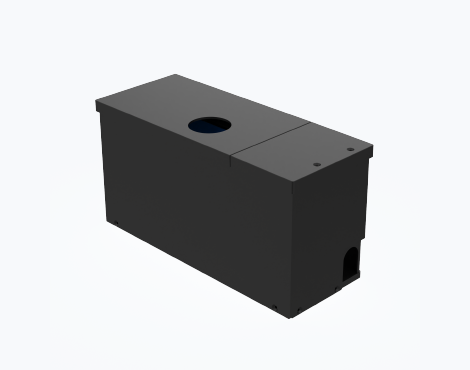

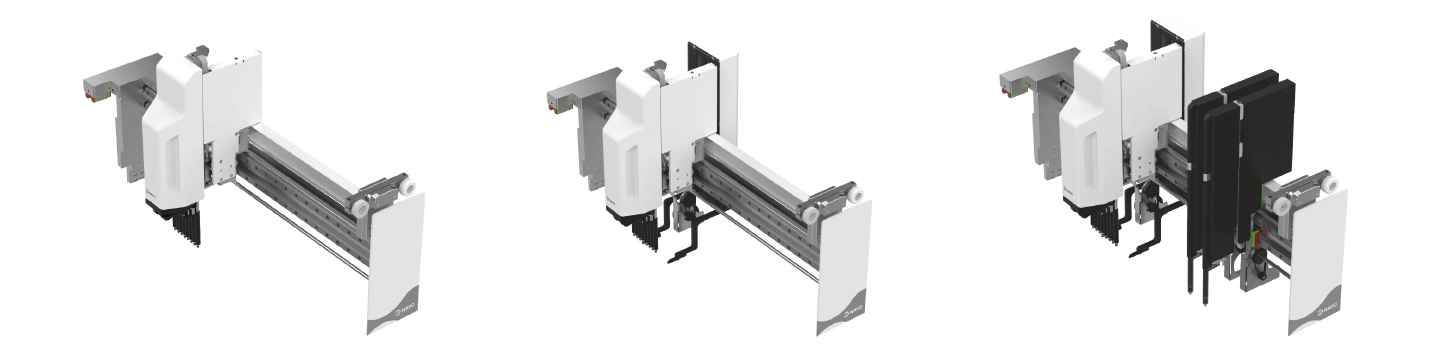

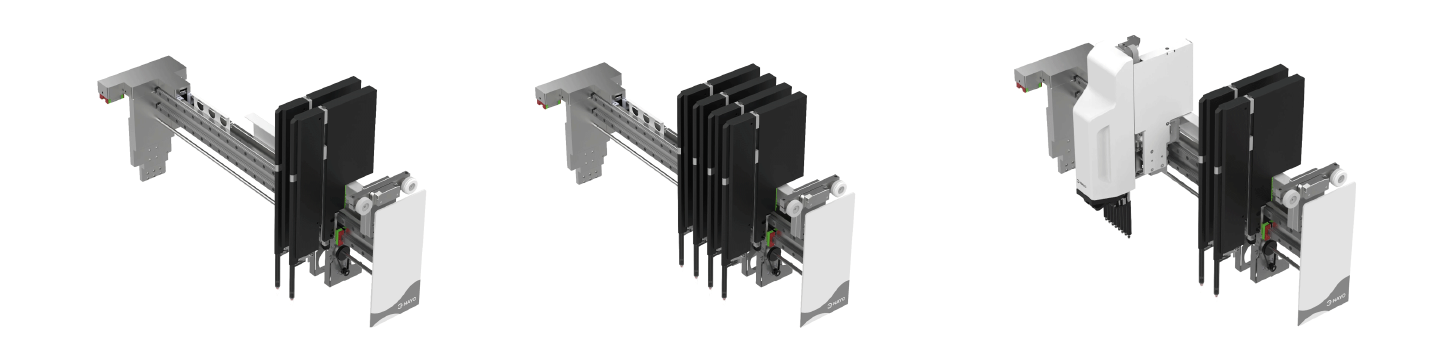

Multi-Function Arm Configuration

The A8 mini meets personalized needs through various combinations of arm configurations.

Switch MFA to Cover Diverse Application Scenarios

Safety & Small Footprint

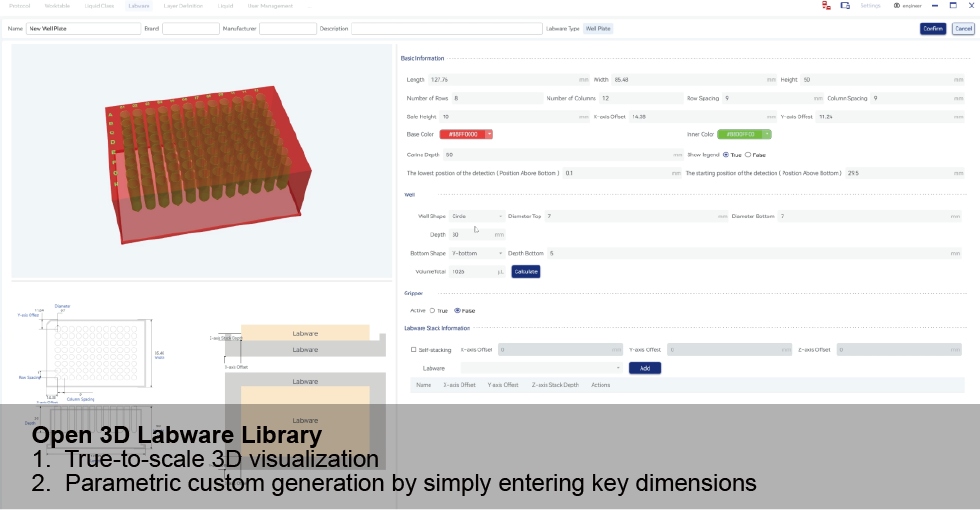

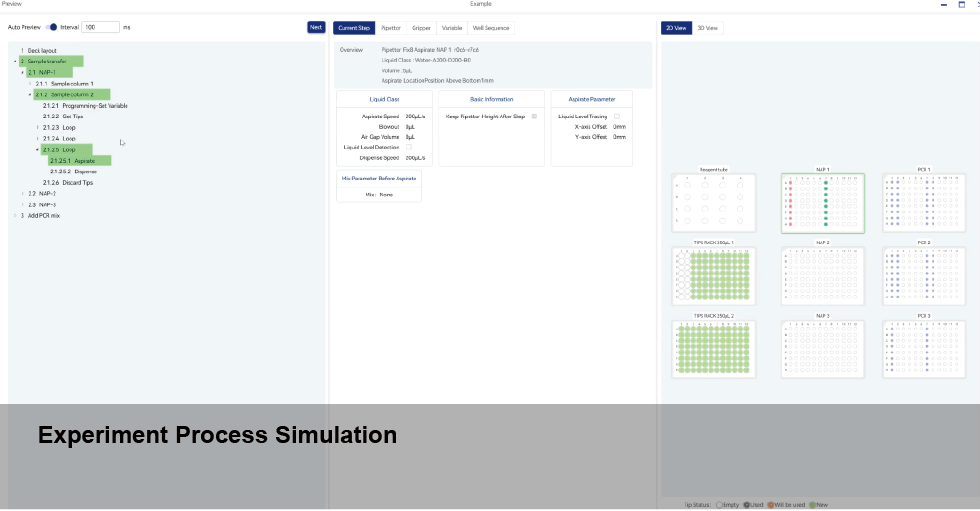

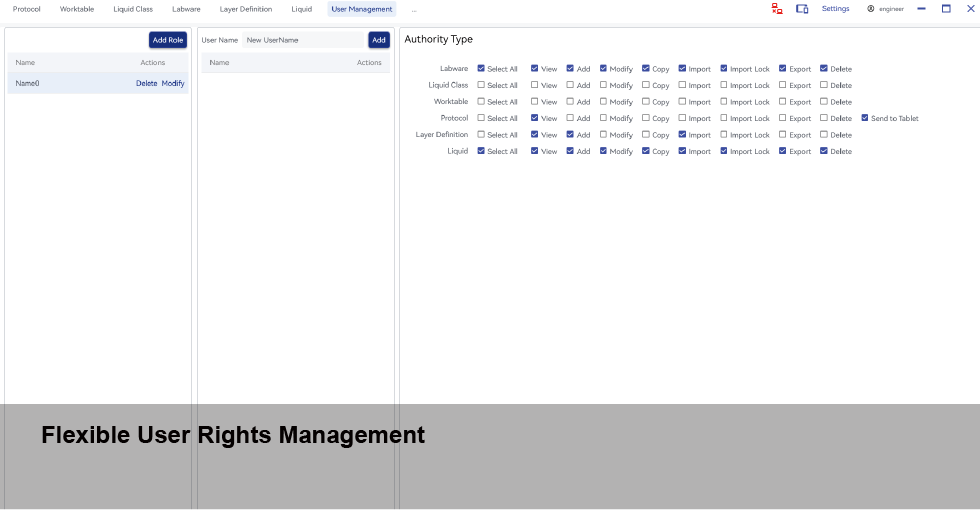

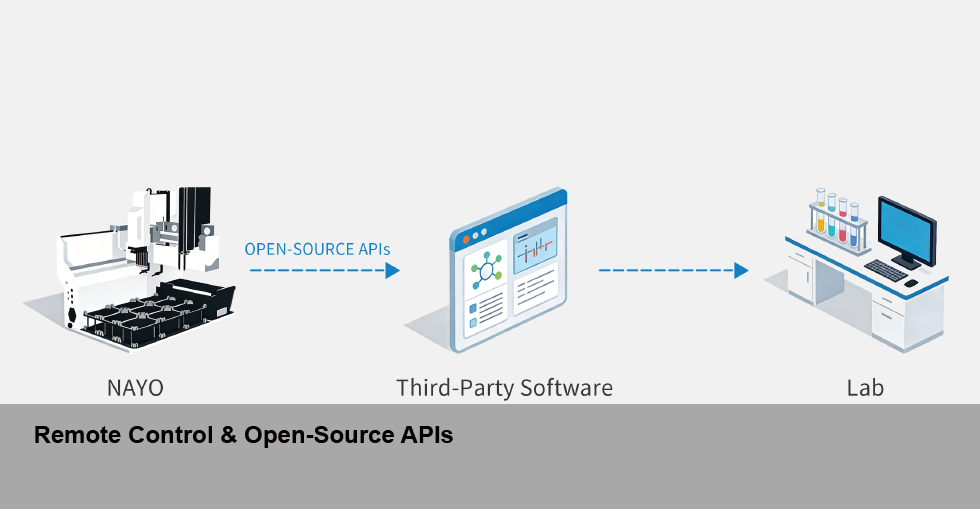

User-Friendly Software

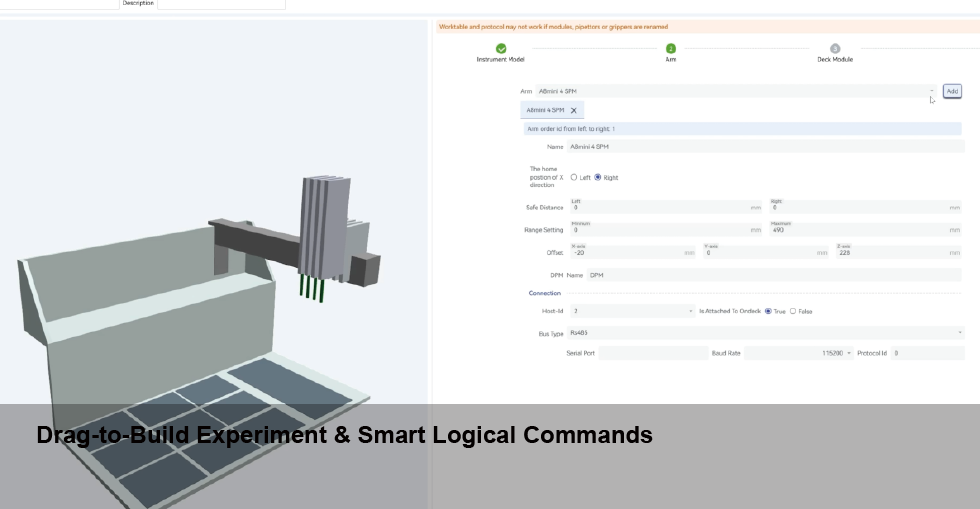

Drag-to-Build Experiment to Realize Quick Operation

<

>