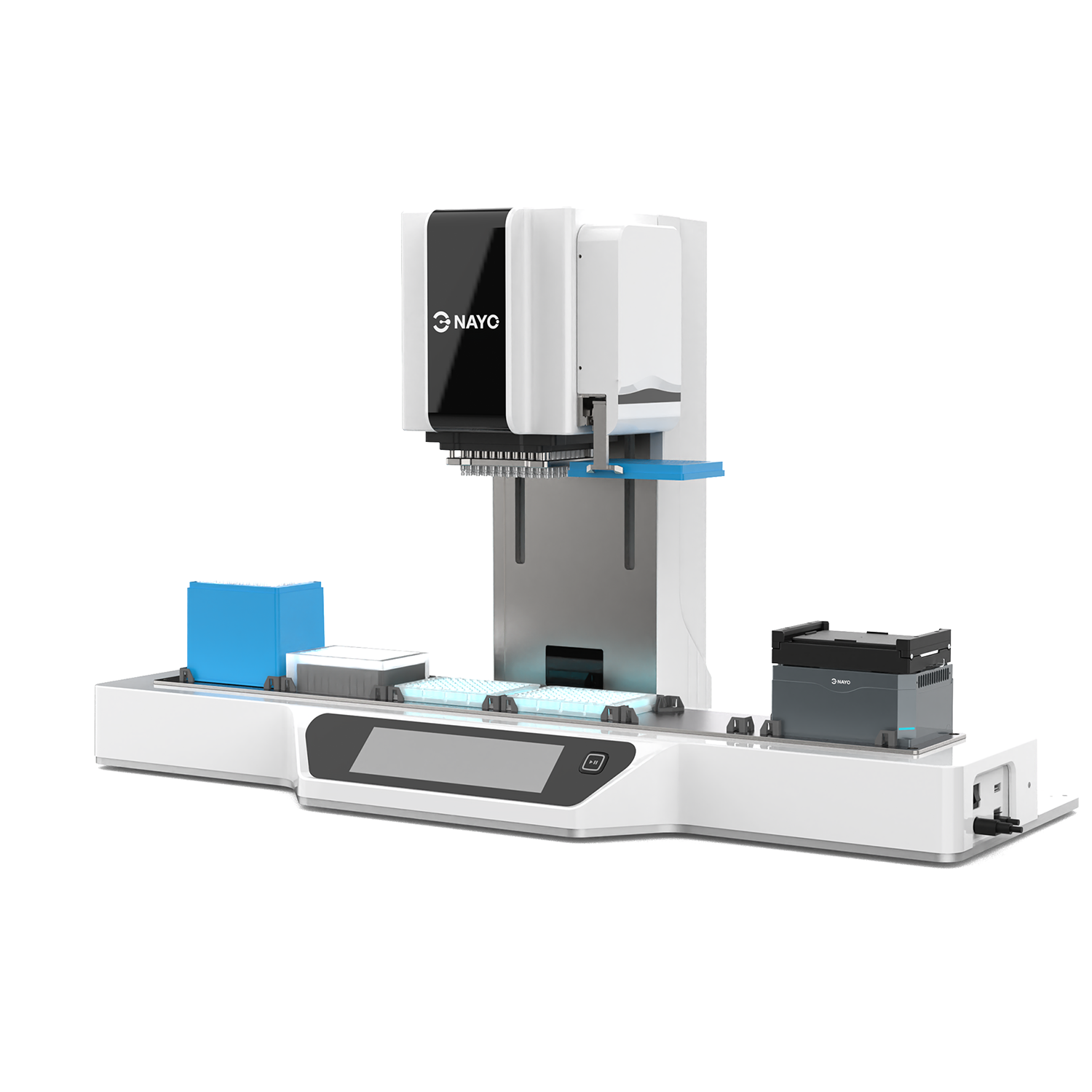

The NAYO N96S is a versatile 96-channel automatic liquid handling workstation capable of accommodating various functional modules. With foundational features such as high-throughput liquid transferring, continuous dispensing, and gradient dilution, it additionally offers plate transferring, magnetic separation, and temperature-controlled shaking functionalities, greatly expanding its application scenarios.

Upgraded servo motors ensure precise control of liquid dispensing

The new sealing design eliminates the occurrence of any liquid leakage

The pipetting module supports fast assembly and disassembly

Plate transfer, magnetic separation, and temperature-controlled shaking functions are available

With a fixed tray structure and dual-axis movement of the pipetting head to reduces horizontal space by 50%

First-generation Sequencing

Nucleic Acid Extraction

Sample Magnetic Bead Purification

PCR and qPCR

Cell Viability Assay

ELISA

Compound Serial Dilution

Reaction System Preparation

Nucleic Acid Extraction

Compact design with integrated electronic (no external control devices required)

Fast mixing speeds up to 5000rpm

Wide temperature range with rapid Heating and cooling rate

Accurate force control gripper: gripper force from 1-16 N, support the transfer of various consumables and integrted modules.

Configurable finger directions: can access peripheral devices to enable a huge array of process automation possibilities.

| Dimensions(W×D×H) | 4 deck position 6 deck position | 711mm×392mm×582mm 998mm×392mm×582mm |

| Pipetting Range | 1-1000μL | |

| Precision | CV<5%@2μL,CV<1% @200μL | |

| Resolution | 0.1μL | |

| Pipetting principle | Air displacement | |

| Function Modules | Heating module, temperature control module, shaking module, temperature-controlled shaking module, magnetic plate | |