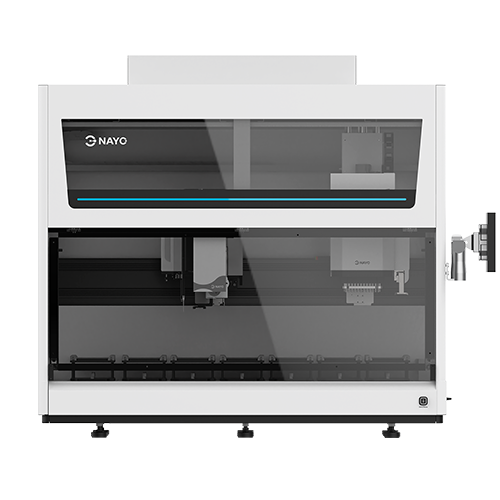

The A96 is fully automated liquid handling workstation for high-throughput applications based on Flexible Architecture of NAYO(FAN). Its modular and scalable design supports the third-party integration. With customizable X-axis deck expansion, various multi-function arm configurations and on-deck modules, it covers diverse application scenarios. Precisely gripping and transferring microplates and tube consumables, it can meet varied liquid handling requirements. Optional HEPA filter hood and UV lights are available for a sterile workspace

2-channel flexible pippetting module

8-channel fixed pippetting module

Plate transportation module

Multiple module integration

Feature pLLD realizes real-time monitoring during pipetting process

Plate present monitoring during plate transportation

Worktable is easily configurable to meet the requirements of workflow

First-generation Sequencing

Nucleic Acid Extraction

Sample Magnetic Bead Purification

PCR and qPCR

NGS

Organoid Drug Sensitivity Testing

Cell Level Detection

Flow Cytometry Sample Preparation

ELISA

HTS Compound Screening

Compound Rearrangement

Compound Serial Dilution

Compound Selection and Rearrangement

PCR

NGS

Blood coagulation

| Dimensions | 790/1240mm(L)×730mm(W)×890mm(H) |

| Weight | 128+kg |

| Power Supply | ~100-240 VAC, 50/60Hz |

| Arm Configurations | Fixed 96-Channel Fixed 96-Channel+Gripper Fixed 96-Channel+Flexible 4-Channel Fixed 96-Channel+Flexible 8-Channel |

| Deck Capacity | 20-35 |

| Pipetting Principle | Air displacement |

| Pipetting Range | 1μL-1000μL |

| Liquid Level Detection | Pressure liquid level detection |

| Precision(CV) | ≤4%≤5μL; ≤1%≤200μL |

| Precision of Arm Movement | ± 0.1 mm |

| Environmental Control | UV & HEPA |