In recent years, China’s industrial automation market has experienced robust growth amid the transformation and upgrading of the manufacturing sector, providing strong support for the development of domestic laboratory automation. According to Mordor Intelligence, the global laboratory automation market was valued at approximately $6.23 billion in 2024 and is projected to reach $8.66 billion by 2029, with a compound annual growth rate (CAGR) of 6.82% during the forecast period (2024–2029).

Currently, different laboratory scenarios are at varying stages of automation. Based on the degree and scale of automation, lab automation can be categorized into four phases: standalone device automation, workstation automation, workflow automation, and intelligent automation. However, these stages do not represent a linear replacement progression but rather a tailored approach based on cost, throughput, research, and customer requirements.

From the perspective of user needs, Luo JunKui, CEO of NAYOLAB, emphasized,

"In the field of lab automation, it’s not the ‘high-end’ features but the stability, consistency and easy-to-use of core products that truly meet customer demands. Achieving or even surpassing the performance benchmarks of imported products should be the focus of China’s laboratory automation industry today. "

A Technical Founder Who Believes "Process Excellence" Outweighs "Technology Novelty "

NAYO globalization

NAYO globalization

As a leading domestic manufacturer of laboratory automation equipment, NAYO was founded in 2016 and has been dedicated to the field for nearly a decade. Headquartered in Shanghai, the company operates a 10,000㎡ R&D and production base in Changshu, Jiangsu, and has established branches in Beijing, Chengdu, and Guangzhou, along with a service center in the U.S. forming an efficient network covering R&D, manufacturing, sales and service. As OEM with core design and manufacturing capabilities, NAYO specializes in customized high-quality automation instruments and component solutions to meet diverse sample pre-processing needs.

CEO Luo JunKui, a seasoned expert with nearly 20 years of experience in precision instrument R&D and industrialization, asserts:"Process excellence outweighs technological novelty."

"Most technologies in life science automation are already mature. Therefore, in industrial and commercial applications, process mastery often determines success more than technological breakthroughs. At this stage, domestic manufacturers should focus less on pursuing 'flashy innovations' or 'cutting-edge technologies' and instead concentrate on delivering solid, high-quality foundational products. The automation industry is essentially a tool industry where the universal trend is toward better quality, more efficiency and easier-to-use. Thus, matching or surpassing the performance standards of imported products should be the priority for local manufacturers."

NAYO embodies this philosophy. We have accumulated numerous "advantageous techniques." Share one case that the flexible seal ring design of pipette tips initially offered reliable leak-proof performance but had a limited lifespan. To overcome this challenge, the R&D team spent 18 months, underwent six rounds of mold optimization, investing millions to extend the tip’s durability from 20,000 cycles to 300,000 cycles, rivaling top international brands.

"For experienced professional users, their ultimate need is not 'automation' but ideal experimental results. By relentlessly refining processes to ensure safety, accuracy, reliability, and traceability in user experiments, NAYO has built a 'differentiated edge' in our customer minds." Luo JunKui concluded.

Focus on Sample Pre-Processing: Delivering Safe, Reliable, Fast-to-Deploy and User-Friendly Automation Products

NAYO’s product portfolio spans five categories: liquid handling platforms, integrated functional instruments, integrated modules, application-specific products and consumables & accessories. By establishing a platform-based technical architecture that combining pipetting platform, motion control platform, software platform and robotics platform, the company enables digital process monitoring and significantly enhancing product usability.

NAYO Product Portfolio

In terms of product strategy, NAYO concentrates resources on select scenarios. The automation products primarily target sample pre-processing, leveraging flexible platform technologies to launch tools such as the A8 mini fully automated pipetting platform tool, N96S 96-channel fully automated pipetting platform tool, A8 pro fully automated liquid workstation, and A96 96-channel fully automated liquid workstation. These products offer secure and cost-effective supply chains, reliable and stable results, short delivery cycles, and user-friendly.

Regarding supply chain and cost, NAYO achieves nearly 100% localization of core modules through in-house R&D and production, ensuring supply chain stability and reducing development costs.

For product reliability and stability, equipment failures in large laboratories can have significant consequences, ranging from sample loss to system-wide disruptions. NAYO prioritizes continuous optimization and upgrades to ensure product stability. Notably, in the fields of blood sample pre-processing and NGS processing equipment, NAYO is one of the few companies in the industry to adopt fully closed-loop servo systems, providing comprehensive process monitoring for sample handling.

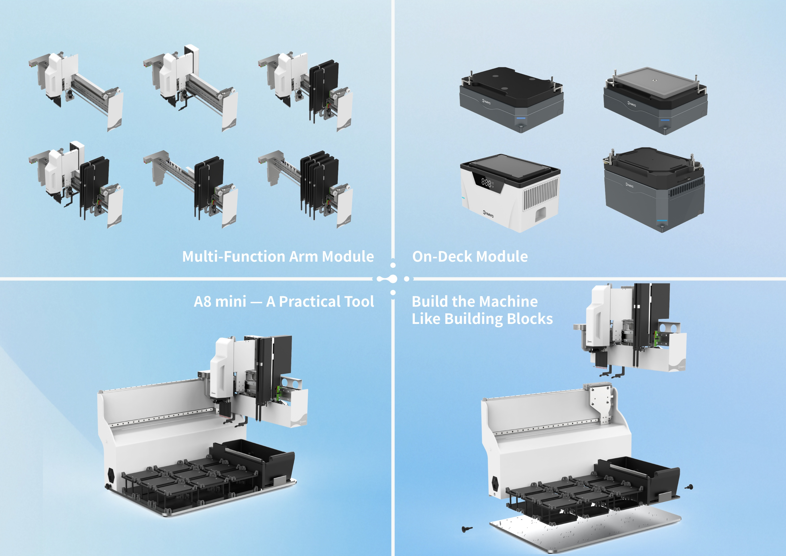

Modular Design

In terms of delivery cycles, modular design enables NAYO to flexibly meet customer needs and significantly shorten lead times. "Laboratory automation equipment has diverse detailed requirements but similar foundational structures. Traditional non-standard customization involves complex and time-consuming processes, from demand analysis, design to parts processing, prototype assembly, and final delivery. In contrast, our modular design platform minimizes customization, slashing development cycles. It allows flexible combination and upgrades of modules to adapt quickly to market changes and diverse application scenarios. For example, our innovative 'sandwich' model—combining diverse multi-function arm modules, on-deck modules with different configurations, and flexible platform architecture—has reduced delivery times from 3 months to less than 30 days," Luo JunKui said.

Additionally, NAYO prioritizes simplicity and user-friendliness in product development. For instance, NAYO self-developed software features intuitive pipetting controls. With unlimited experiment lists, user-editable workflows with auto-save functionality, a built-in consumables database and multiple pipetting modes, users can significantly reduce workflow editing time by adding or defining new consumables, precisely positioning tips, calculating and adjusting aspiration/dispensing depths and angles. The software also includes logical self-checking which can provide real-time error alerts and solutions during experiment design.

Based on these advantages, NAYO products have expanded beyond traditional medical applications into agriculture, academic research and other fields. The clientele includes domestic pharmaceutical companies such as Innovent Biologics, GenScript, CTTQ Pharma, TASLY, and WuXi AppTec; IVD enterprises like BGI, Revvity, KingMed Diagnostics, and Sansure Biotech; agricultural and livestock firms such as Longping High-Tech, MolBreeding, Higentec, Zoetis, and WIN-ALL Hi-TEH SEED; as well as government agencies like customs, public security bureaus, health commissions, and CDC centers. Currently, NAYO serves over 6,000 customers across all 31 provinces in China, with annual sales surpassing RMB 100 million as early as 2020.

A8 Mini Validates NAYO’s Global Strategy: Winning Over Overseas Users with Cutting-Edge Technology

A8 mini

With growing capabilities in domestic automation equipment, NAYO has expanded to over 10 overseas markets (e.g., Singapore, European countries, and the U.S.), where overseas sales now drive most of its revenue.

Recently, NAYO achieved another milestone in its global expansion: the compact automated pipetting platform tool — A8 mini gained recognition from international customers. The core value of the A8 mini lies in its ability to deliver powerful laboratory automation functions within an ultra-compact footprint (665mm × 532mm × 610mm), compatible with standard Class II biosafety cabinets (BSCs). This provides a critical safety barrier for high-protection workflows such as cell culture and pathogenic sample pre-processing.

In terms of flexibility, the A8 mini features a modular, tool-free design: users can select and assemble arms with different pipetting modules (from fixed 8-channel to flexible 4-channel configurations) to suit various applications. All modules cover a full pipetting range of 1–1000μL, enabling precise liquid handling from micro-volume to large volumes simply by replacing tips—no module changes required, significantly improving efficiency. A built-in pressure sensor ensures reliable liquid level detection for accurate liquid aspiration.

For usability, the A8 mini can be used to a wide range of laboratory workflows. Its self-developed software offers drag-and-build experiments design, enabling users to effortlessly execute tasks like sample transfer, reagent addition, complex gradient dilution, reaction setup, and mixing & resuspension.

In terms of safety and stability, the A8 mini is equipped with self-developed on-deck functional modules that support plug-and-play via reserved interfaces without requiring additional controllers. Its force-controlled gripper intelligently adjusts force based on consumable weight, effectively preventing microplates, deep-well plates, and other labware from bending or slipping during handling. Additionally, the servo-motor system with force feedback technology detects pipetting obstacles and triggers instant alerts, ensuring fail-safe operation and a hassle-free user experience.

Various Application Scenarios

Overall, by combining various configurations, compact design and modular self-assembly, the A8 mini has become a practical automated pipetting tool for enhancing efficiency, reproducibility, and operational safety in genomics, cell biology, proteomics, drug development and clinical diagnostics.

The A8 mini’s design philosophy reflects NAYO’s globalization strategy. Luo JunKui shared with VcBeat:

"Overseas users are highly professional and value intellectual property. Thus, our global strategy focuses on innovation and product stability, which are key to earning international recognition and repurchasing. The overseas market is a providing ground—it doesn’t reward clever strategies and gorgeous packaging but real product competence and pricing strategies. In this regard, we don’t strictly differentiate between domestic and overseas markets. As Mr. Lin YuTang wrote in Moment in Peking:‘Beneath the skin, human souls are alike. What resonates with one culture will resonate with another.’ We believe users across markets are fundamentally the same, though pricing differs, with higher premium potential abroad."

Luo JunKui concluded:

"Customers don’t pay for ‘automation’ alone, nor just for ‘low prices’—they pay for perceived value. We are committed to delivering higher quality, more efficient, cost-effective and use-friendly lab automation solutions for laboratory efficiency and convenience globally."

Resource from: https://www.vbdata.cn/1519027053